Product Description

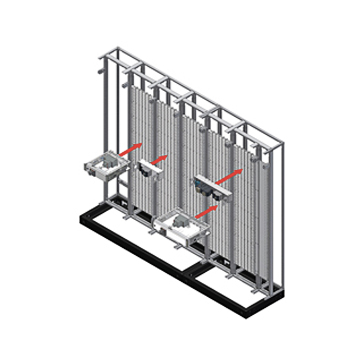

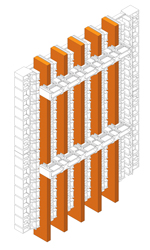

The vertical bus bars are mounted in a flat bus bar holder that doubles as a form 4 separation plate and a plug in base. It is called the motherboard. These motherboards are mounted from top to bottom in each section.

The vertical bus bars are mounted in a flat bus bar holder that doubles as a form 4 separation plate and a plug in base. It is called the motherboard. These motherboards are mounted from top to bottom in each section.

This means that no matter where you choose to insert the withdrawable or removable unit it connects with the bus bars on the back of the motherboard.

Each section can carry 1250 Amp so there is plenty of space for extra units once the panel is installed.

While designing your future Plug & Power panel we recommend having at least 30% free extra space for expansion.

For instance for that extra scanner the hospital just installed, the extra shop in the mall, the extra compressor at the ice cream factory, even the extra pump on the oil platform etc.

For instance for that extra scanner the hospital just installed, the extra shop in the mall, the extra compressor at the ice cream factory, even the extra pump on the oil platform etc.

Medical equipment, CNC machines, process plants etc. are being developed and improved almost at the same speed as mobile phones. Consultants and end users have to accommodate this when they make new investments in construction.

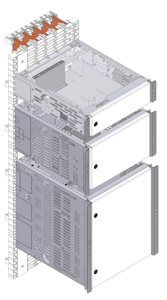

Plug & Power means the consultants are no longer tied to strict specifications since they can make last minute modifications at any point during assembly, installation and during use.

Now you have the freedom to Plug in and Power up anything you need, anywhere you like in the panel, at any given time.

Plug & Power has furthermore been designed for easy and quick assembly so the panel builder saves a considerable amount of time in the workshop. The labor cost of bolting connections to bus bars of breakers and motor starters is higher compared to just plugging them in. Breakers /motor starters can conveniently be pre-assembled on a worktable!